Hatch Cover

Your current locationú║ HOME > Hatch Cover

| Hatch Cover : |

| 1.Technical consulting when the hatch cover damaged 2.Steel structure fabraction ,hatch cover hydraulic system repair. 3.Hatch cover emergency maintenance in the yard and port or sea going. 4.Cargo handling and stowage system for contain ship.Lashing spares supply. 5.Hydraulic system design .Installation and debug of pump station and hydraulic cylinder . 6.Rubber packing ,drving chain, cleat, sprocket wheel ,hatch roller,bearing pad , hydraulic cylinder supply 7.Hatch cover service engineer inspect onboard quick analysis of the situation and supervise job when docking |

| Service type range: | Service Brand : | |

| 1.Folding type hatch cover 2.Side rolling hatch cover 3.Piggy back hatch cover 4.Hight lift hatch cover 5.Tween Deck hatch cover |

|

1.TTS 2.MacGregor 3.MacGregor-Navire 4.Deutsche MacGregor 5.Nakata Mac Kayaba 6.Seohae 7.MACOR Neptun 8.Tsuji Heavy Industries |

| Common problems influence the hatch cover operations and watertight |

|

Aged and over compressed rubber

|

Rusty and damaged rubber channel |

Wear down pins

|

|

|

|

|

Damaged sprocket wheel

|

Not rolling stuck wheel

|

Aged hydraulic cylinder seal kits

|

|

|

|

|

Unfunction wheel lifter

|

Wear-down drving chain

|

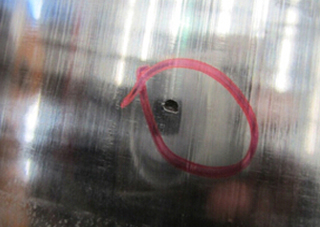

Hydraulic cylinder scratch and damaged

|

|

|

|

| Watertight: | |

| Keep the hatch cover watertight is very important to the cargo, there many reason can lead to the hatch leaking. Usually the packing aged ,rubber channel and bearing pad & wheel lifter worn out make the rubber can not be compressed enough to prevent the warter leaking inside the cargo .Here our service team are availible to be onboard to cure the leakage.After the job finish the hatch cover can pass the Hose test or the ultrasonic testing to reach the CLASS Survey and the P&I SURVEY requirement. |

|

| ON BOARD EMERGENCY SERVICE | |

| Today in the shipping indsutry, to keep the cargo clean and safe is a big issue, the hatch cover is a key factor to avoid anything worse happen.But the hatch cover is a very complex system with heavy steel structure and hydraculic component.when the hatch cover is in trouble even a small problem sometimes. it will be take long time for the owner figure out to find a solution We have qualified service engineers in our service team to help you with both proactive (preventive and planned), on-demand and emergency maintenance.Our goal is to prevent problems and downtime Assuring optimum equipment availability for the ship operator and owner, our planned maintenance concept rests on the solid foundation of our worldwide service network. For support services, our service team are. available in seven days a week |

|

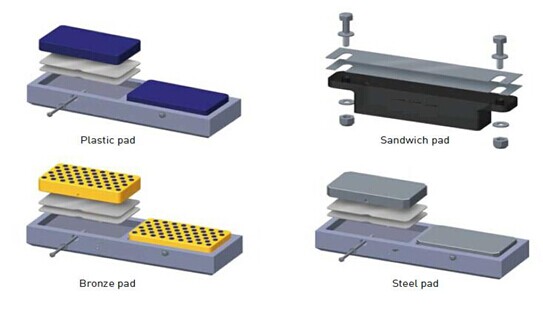

| Support Pad : |  |

| .Mininal wear-down .Best design and material Longer life to reduce cost |

| Rubber Seal : |  |

| Rubber seal was used for the hatch cover when closed to compress the seals keep thecargo dry from the water. The sealing between the hatch cover and coaming can be achieved by many different types of rubber packing. The larger ship it is,the bigger the movement rubber packing bettwen the hatch cover and coaming will be.The sliding rubber packing is press againest the flat surface and pressed more flexible and bigger hull deformations. This issue was well solved by the sliding rubber seal. |

|

|

|